Almost all beneficiation plants have room for improvement in indicators and production capacity, as well as for cost reduction. Many beneficiation plants have a lot of room for improvement and decrease. If you take over and comprehensively manage a beneficiation plant, is there any way to quickly improve its production indicators, such as increasing the beneficiation recovery rate by at least 0.5% or more within one or two months, increasing production capacity by at least 5% or more, and reducing the per ton ore consumption to at least 95% or even higher.

The answer is affirmative! As the saying goes, “hit the snake and hit the seven inches”, just five words, express the key and essence of management: target management is the foundation of management. Snake hunting is the goal, discovering the target, tracking the target, and achieving the target is the goal; Playing seven inches is the key and the key. The so-called stable, accurate, fast, and good ones are also the ones that can win with one move. What are the “seven inches” of mineral processing production management work? It must be the key and key link in management, and what is the focus and key of the selection work?

Even long-term practitioners may be at a loss and unable to answer at first glance. If you analyze from the perspective of goal management, you will suddenly understand that the goal of mineral processing is to use management methods and sorting techniques to separate useful minerals and gangue as much as possible in a relatively safe, environmentally friendly, and economically efficient way, while obtaining the mineral products needed by the market.

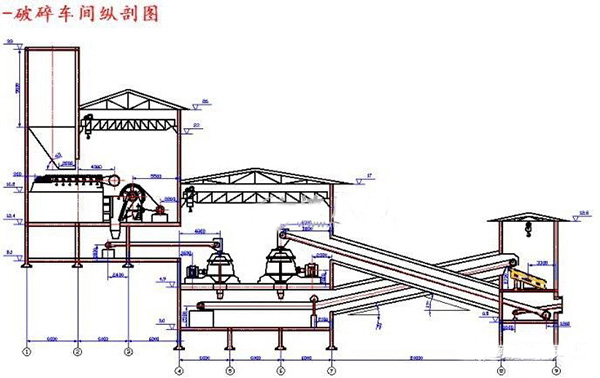

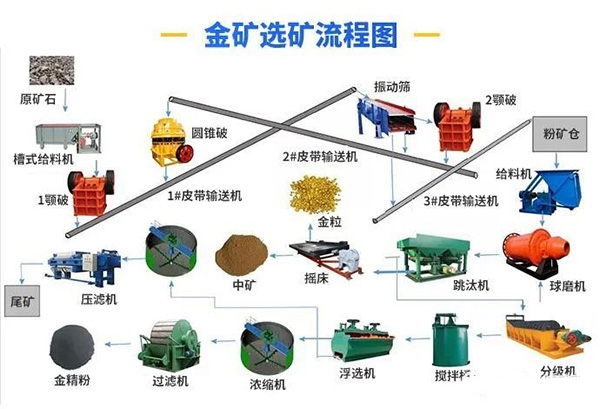

To separate useful minerals from gangue, it is necessary to first perform monomer dissociation on the useful minerals, which is achieved through the beneficiation process and equipment. The safety and economy of monomer dissociation must be controlled, and the results of monomer dissociation must be ensured. Secondly, it is necessary to send the fully dissociated ore to a suitable working environment, and have dedicated personnel and high-performance professional equipment complete the sorting operation in a safe, environmentally friendly, and cost-effective manner. So, before carrying out mineral processing work, it is still the most important and indispensable to clarify and keep in mind the work objectives, and to carry out work closely around them.

All work carried out around the goal always has priorities, priorities, and order. Everything can grasp the key points and key points, be willing to sacrifice the essence for the end, and have a sequence and order. It must be able to outline and lead the work, enabling the work situation to be quickly opened up, the work to be efficiently carried out, and problems and difficulties to be solved and overcome in a timely manner.

However, any work cannot be carried out without people, machines, materials, methods, and the environment. The characteristics of the industrial era and the future information age are that people use machine tools, digital information network technology, automation and intelligent control technology, and use appropriate methods to send raw materials into a suitable environment to produce various target products, and the production and processing of minerals is no more than this.

As a management personnel engaged in mineral processing production and operation, finding suitable personnel and managing them well is the first element (good management is the foundation of all work, that is, good personnel organization, good work plans, and good process control leadership); The second factor is to choose and use equipment well, ensuring that it always maintains good condition and performance, which is the second element (if you want to make it, you must first sharpen your tools. Mineral processing equipment can be said to be a pot and stove for mineral processing, but poor management can make it difficult for a skilled woman to cook without a pot or stove). As a professional in mineral processing technology, if we temporarily set

aside human-machine factors, which tasks in the remaining “method, material, and environment” are the key focus and priority solutions

Goal orientation can always provide direction for work. Since the goal of mineral processing is already clear, who will choose is also clear (personnel and equipment). Is it time to solve the problem of how to choose other options? The quickest and most effective way to solve this problem is to obtain representative mineral processing experimental research reports as soon as possible and carefully study them, The purpose is to grasp the properties of the ore (including physical and chemical properties, mineral composition, useful mineral embedding particle size and symbiotic relationship, gangue and impurities, true density, difficulty in grinding and selection, as well as the selection of similar domestic ores), to master the equipment and process flow (method) determined through systematic beneficiation experiments, the requirements for concentration, fineness, temperature, and pH of the selected ore The requirements for the addition of selected drugs (environment), as well as the differences between the report content and the actual production situation; At the same time, in order to better and more conveniently guide production, it is necessary to make concise summary texts of reports in a timely manner. If necessary, representative ore samples can be taken again and systematic research experiments on mineral processing can be rearranged as soon as possible.

The goal of mineral processing is achieved through the sorting production system, and conducting a thorough inspection and evaluation of the sorting production system in a timely manner is the key to doing a good job in sorting work. How to evaluate the effectiveness of the selection system is to arrange targeted production system process inspections as soon as conditions are ripe, mainly focusing on local and comprehensive process investigations of production status, technical conditions, technical indicators, equipment performance and working conditions, raw material properties, the direction of metal loss, and related parameters. While conducting quality inspections of the selection process, it is important to focus on understanding whether the particle size of the feed mill is stable and has the possibility of reduction. Check whether the feeding amount of the mill is uniform, continuous, sufficient, and stable. Check whether the filling rate and steel ball ratio of the mill are appropriate. Check whether the grinding concentration and grinding time meet the requirements. Check whether the calculated sand return amount is within a reasonable range. Check whether the condition of the intermediate ore is suitable. Check whether the selected concentration and fineness are optimal, Check if there are any issues with the addition of reagents, calculate whether the flotation time can be guaranteed, evaluate whether the equipment performance is good and running smoothly, evaluate whether the production system and process are complete and need optimization, etc. The purpose of the above work is to timely identify and solve problems. The safety production and operation management of mineral processing should always adhere to the focus and goal of ensuring product quality, improving recovery rate, increasing production capacity, and energy conservation and consumption reduction in the selection work.

Engaging in mineral processing production management, if you can quickly grasp the above links, it will definitely improve the efficiency and effectiveness of mineral processing in a short period of time. The development of enterprises and society may focus on talent, equipment, technology, resources, etc. in a short period of time, but ultimately, it is management. Once technology breaks through, there will be a steady period, and management is endless and must always keep up with the times, making it even more difficult to replicate. With the tremendous progress of information network technology, management will become relatively simple and management efficiency will be greatly improved, but it will become increasingly important and indispensable.

The development of mineral resources on Earth is constantly increasing, as they are irreversible and irreplaceable, and will become increasingly scarce and precious. Improving utilization efficiency and enhancing utilization technology has become the pursuit and dream of professionals.